Online Service

Online Service

Top

Top

Service

Service

Feedback

Feedback

Diverted Acidizing Fluids VES2-11

Apperance:Pale yellow to brown liquid

Flash Point (Closed-up) ,('C ):Below 15ºC

Density range(g/cm³):0.95-1.05

PH: 6.0-9.0

Analysis Features:soluble in water and acid

You May Like

You May Like

Product details

Description

Due to differences in the reservoir permeability, high permeable interval acid treatment, and the vast majority of low permeability reservoir, has not been acidification reconstruction. Lead to acidification effect is poorer. Using viscoelastic acidification diverter acidification process will improve the stimulating. At the beginning of the construction, the high permeable formation or natural fracture and inspiratory acid, as you progress through the acidification acid viscosity increased, had the high permeable zone of low permeable formation becomes. Permeable zone of permeable zone in making start acid absorption, also stuck into low permeable formation, low permeability layer became relatively high permeable formation, low permeability layer to take acid at this time. Owing to the intelligent stiffen effect, make the whole long uniform reservoir section of acidification, mining the most almost no contribution to the oil and gas in low permeability reservoir potential.

Appearance: Pale yellow to brown liquid

pH(1%) 6.0-9.0

Solubility:

In water Soluble

Inacid Soluble

Specific gravity 0.95-1.05

Pour-point (ºC) Below 15ºC

Application

Acid Diverter VES2-11, recommended dosage is 3 to 8.0% (for example, 30-80 kg/m3).With the acid process, uniform dosage adding hydrochloric acid product design cycle, product good compatibility with all kinds of acid additives, Acidification of the viscoelastic diverter configuration after corrosion inhibitor. The maximum use temperature of the product is up to 150℃。

Features

The ability to divert acid at temperatures up to 300。F/150℃during acid stimulation operations. With the use of corrosion inhibitor BA2-11VES, high temperature rheological performance good.

Diverted Acidizing Fluids

In order to help coiled tubing service providersunderstand the performance ofdiverted acidizing Fluids , SichuanEnergy Technology Co., Ltd, carried out the series experimental tests and presented the test results respectively.

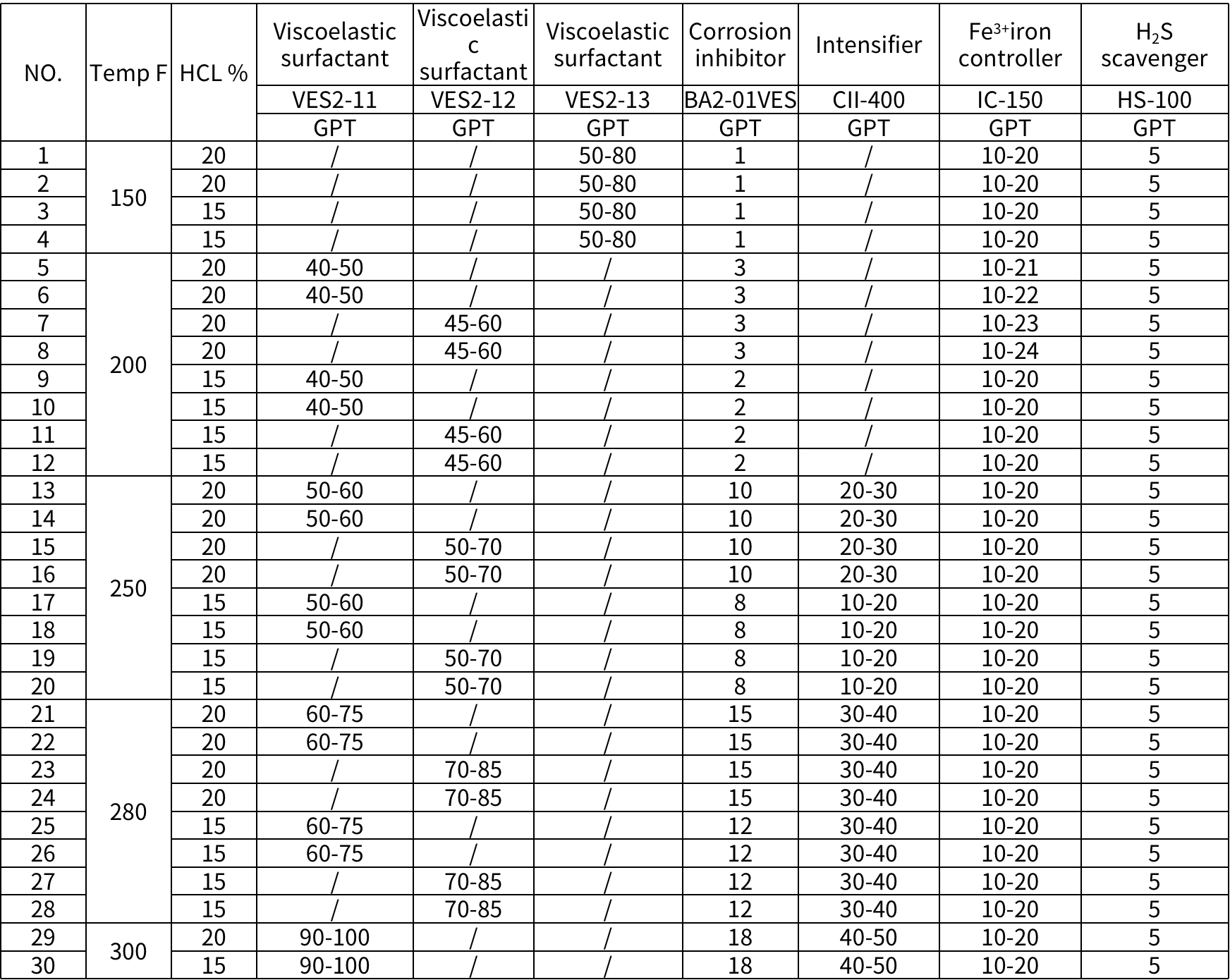

Table 1 Recipe ofDiverted Acidizing Fluids

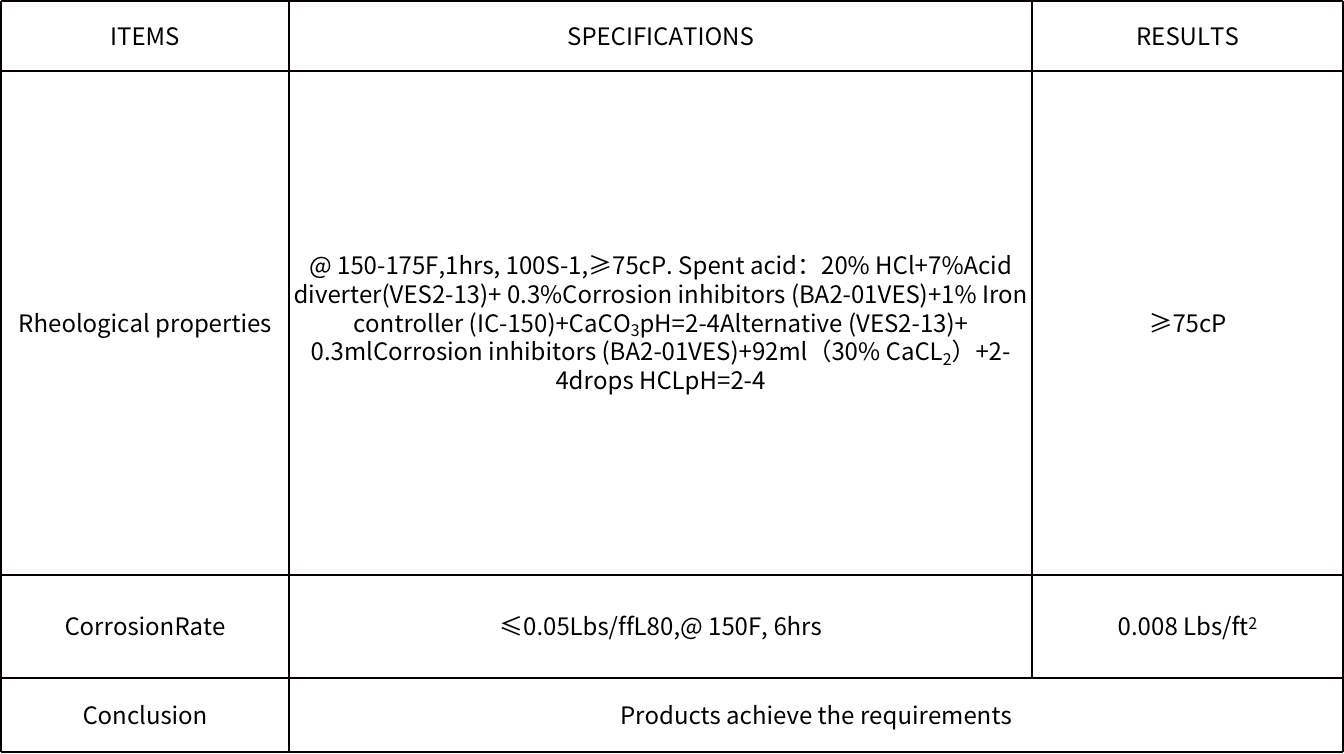

Table2 Indicators of Diverted Acidizing Fluid(150-175F)

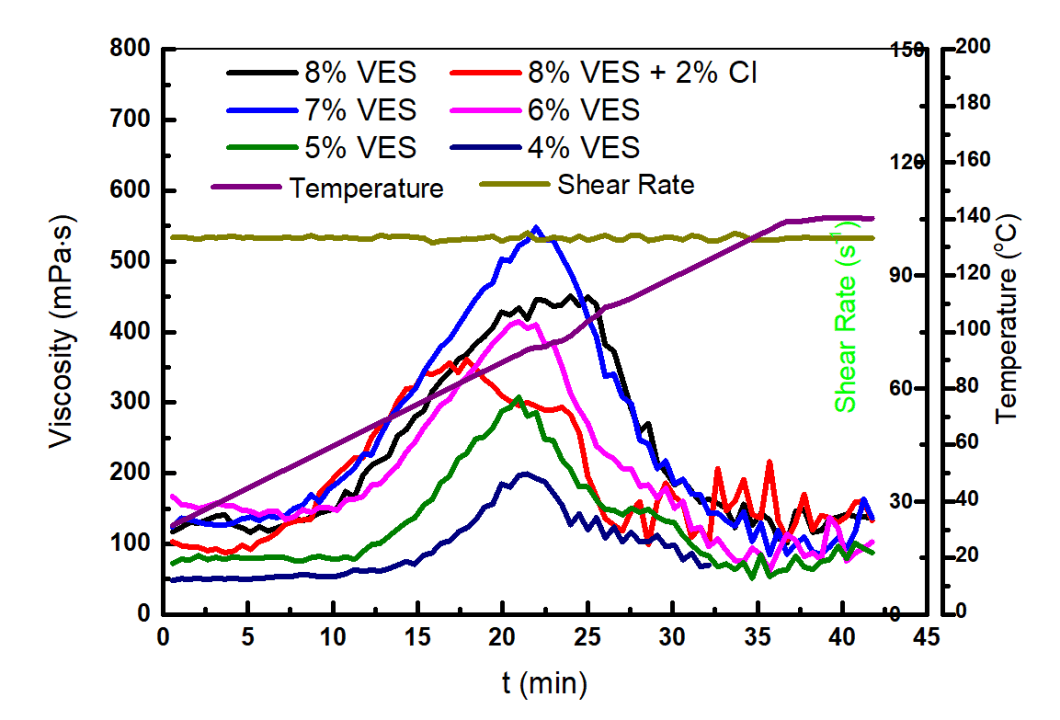

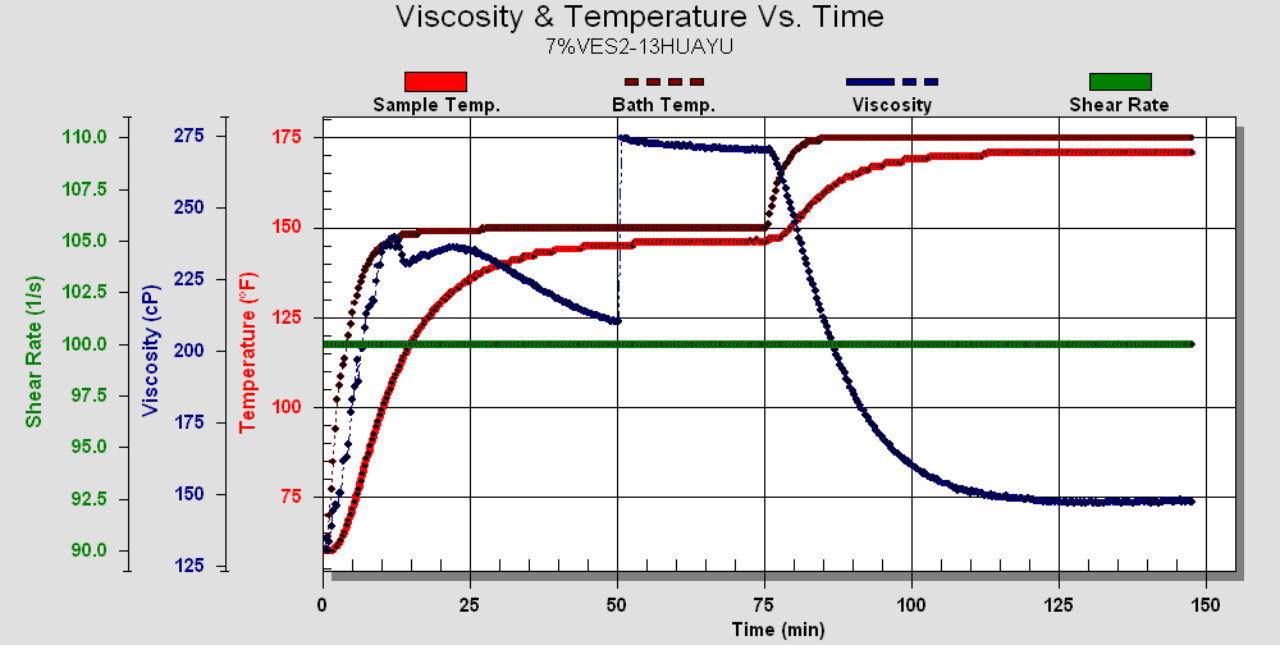

Figure 2 Rheological curve of 20% HCl diverted acidizing fluid @ 175F

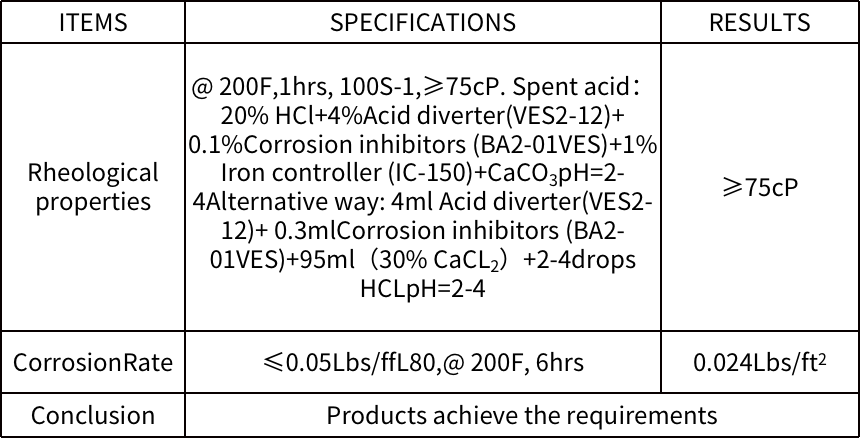

Table3 Indicators of Diverted Acidizing Fluid(200F)

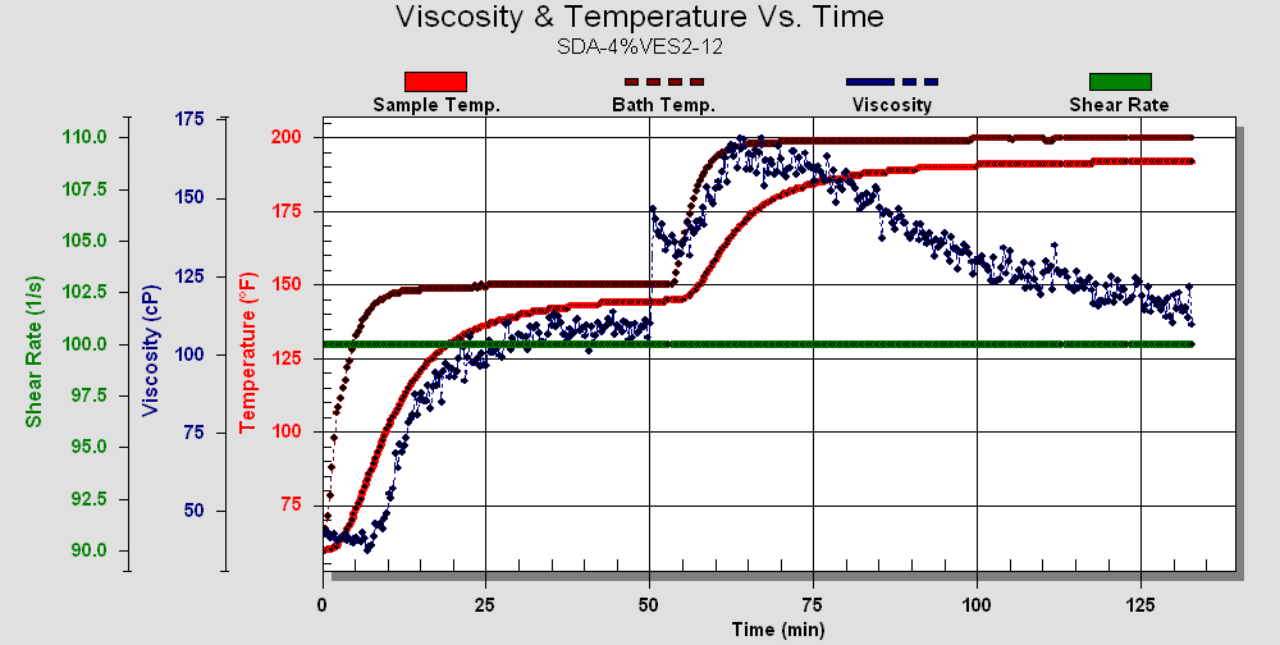

Figure 2 Rheological curve of 20% HCl diverted acidizing fluid @ 200F

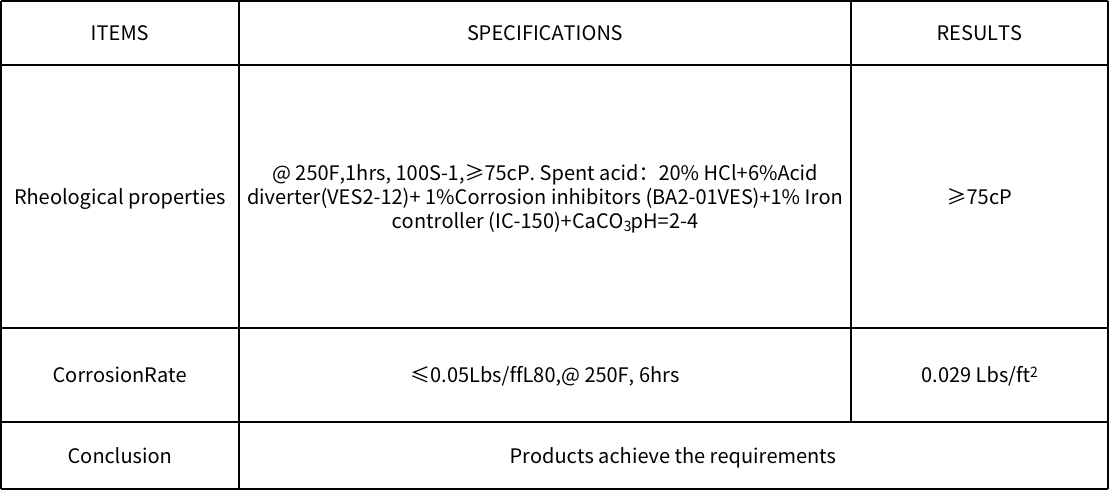

Table4 Indicators of Diverted Acidizing Fluid(250F)

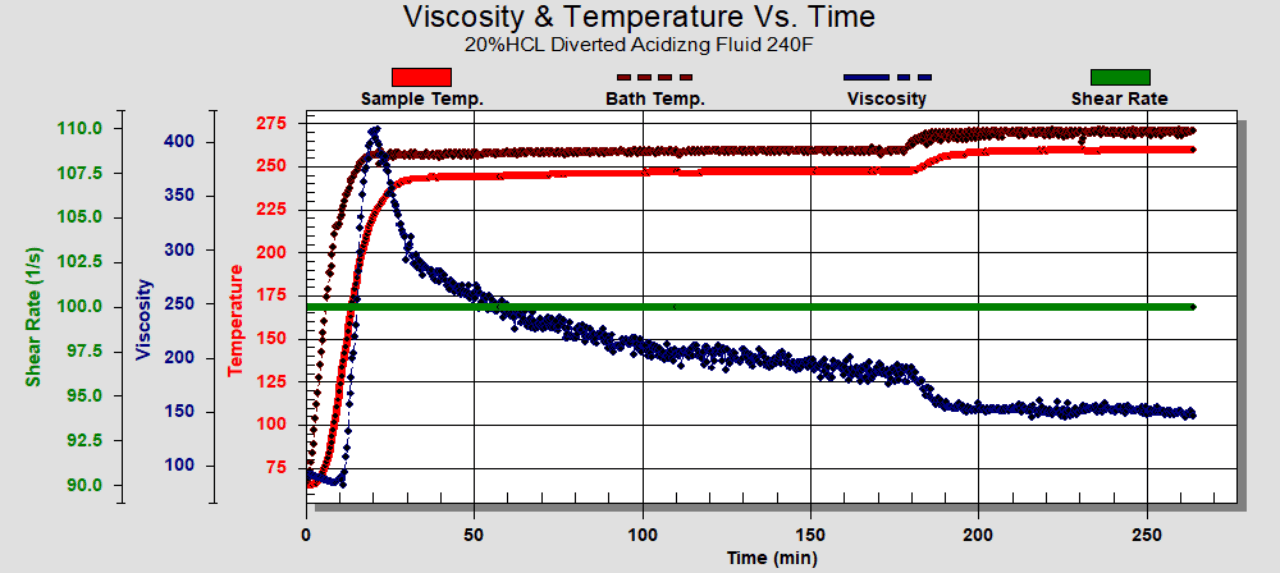

Figure 3 Rheological curve of 20% HCl diverted acidizing fluid @ 250F

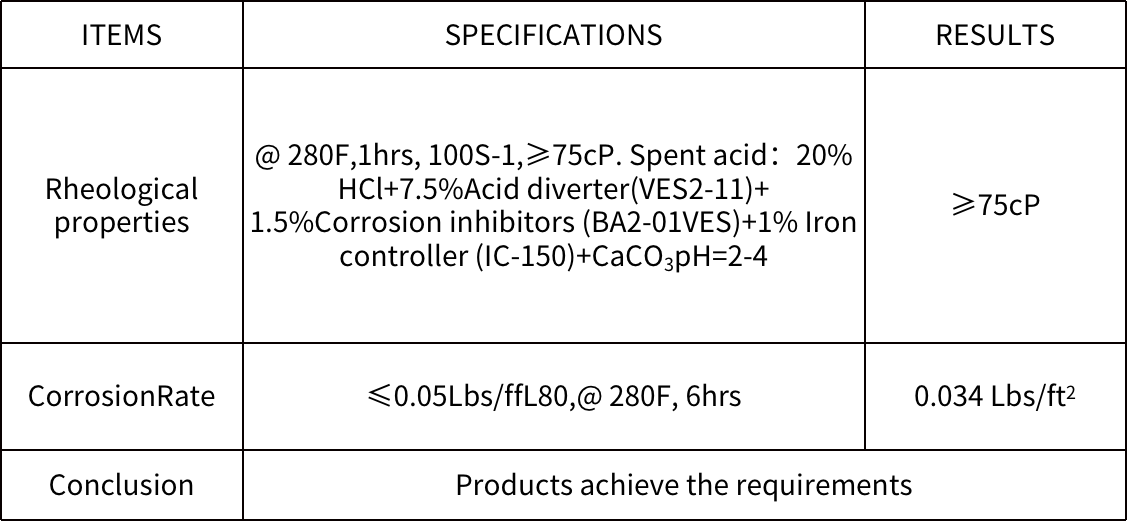

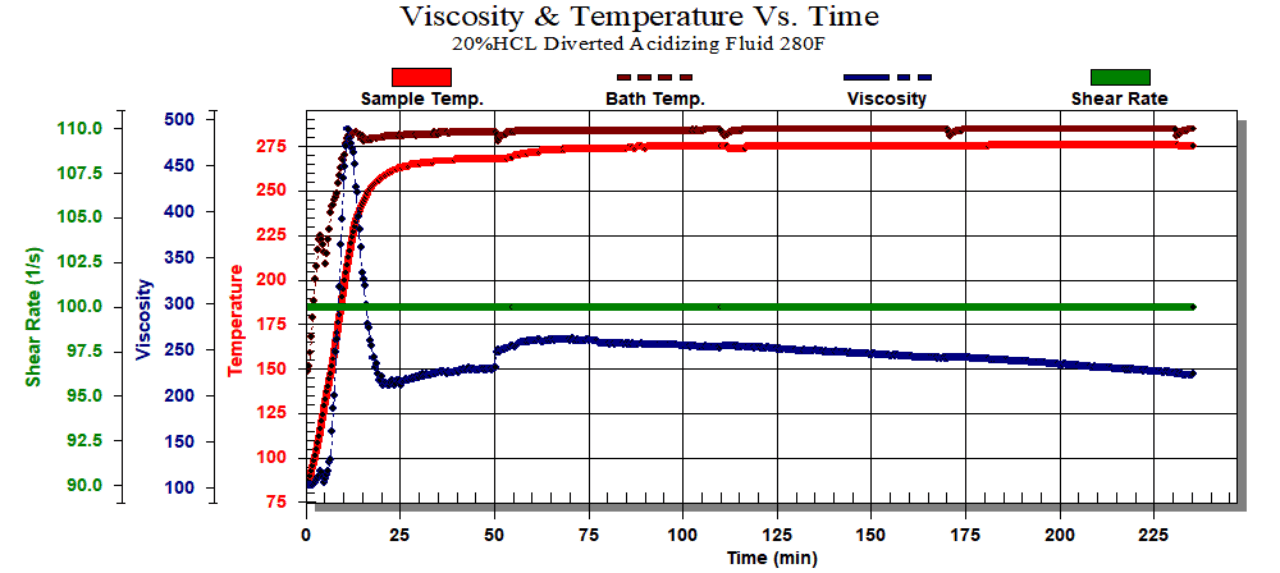

Table5 Indicators of Diverted Acidizing Fluid(280F)

Figure 4 Rheological curve of 20% HCl diverted acidizing fluid @ 280F

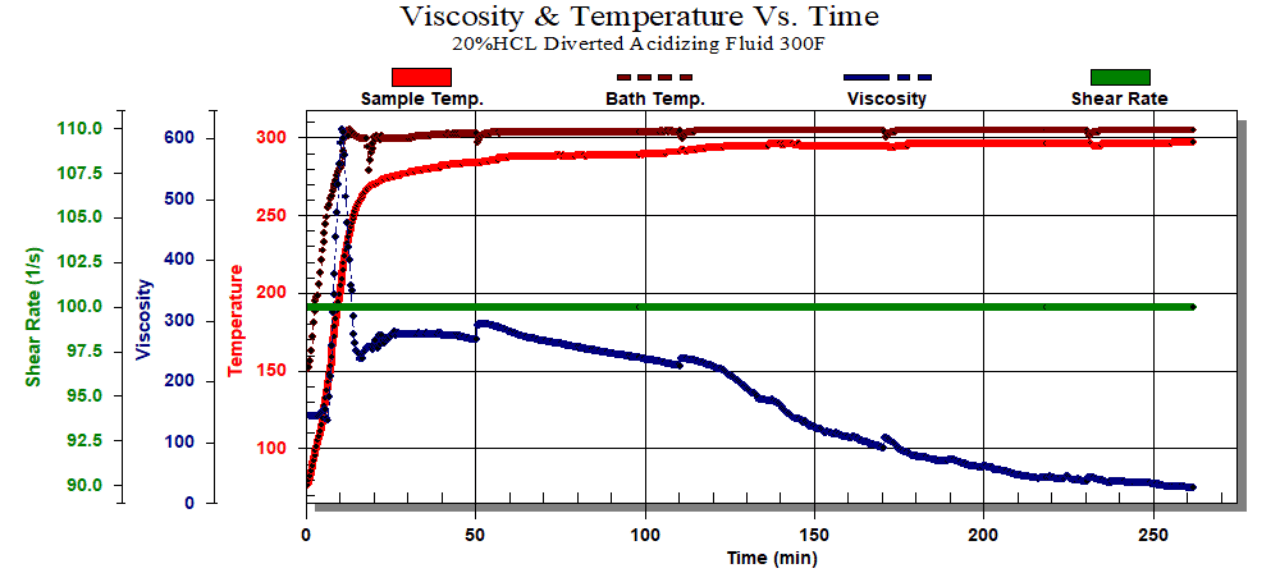

Table6 Indicators of Diverted Acidizing Fluid(300F)

Figure 5 Rheological curve of 20% HCl diverted acidizing fluid @ 300F

Attachment

1. Test of pH value

1) Loading 100 ml sample into 250 ml beaker.

2) Place the beaker in a water bath and keep the temperature at 25℃.

3) Check the pH meter.

4) The pH value of the sample is measured by pH meter, record it.

2. Test methods of corrosion rate

1) Preparation of desired concentration HClacidizingfluid

The acid solution was prepared as acidizing fluid recipe.

① The prepared 200ml of the desired concentration HCl acidizing fluid was poured into the liner respectively;

② Immersed the pre-weighed and measured two coupons into the acid solution;

③ Put the liner into the corrosion reactor and covered lid;

④ Warmed up the corrosion reactor to desired temperature, then kept reaction for desired hours;

⑤ Released pressure and opened lid, took out the liner from the corrosion reactor, then took out the coupons from the liner, wiped, cleaned and weighed;

⑥ Calculated the corrosion rate at different time, the unit is Lbs/Ft2;

⑦ Checked if the coupon was with corrosive pitting; if yes, record it.

3. Test methods ofRheological

1) Preparation of Acid Solution:

The acid solution was prepared as diverted acidizing fluid recipe.

2) Residual Acid Preparation of HCl Diverted Fluid:

Added excess calcium carbonate to 100ml of HCl diverted fluid, reacted to the pH value around3 to4, and removed excess calcium carbonate by centrifugation.

3) Rheological Test:

The residual acid was transferred to aGRACE M5600 rheometer, and the temperature was raised from68°F to a specified temperature. The temperature gradient was carried out according toAPI39 , and the shear rate was 100s-1.

Global Hotline

+86 400-881-5588

If you have any questions, please contact the customer service email: servic@atoilgas.com

Service Time:

Monday to Friday, 10:00 to 17:00 Beijing Time

Scan and follow us

Scan and follow us