Online Service

Online Service

Top

Top

Service

Service

Feedback

Feedback

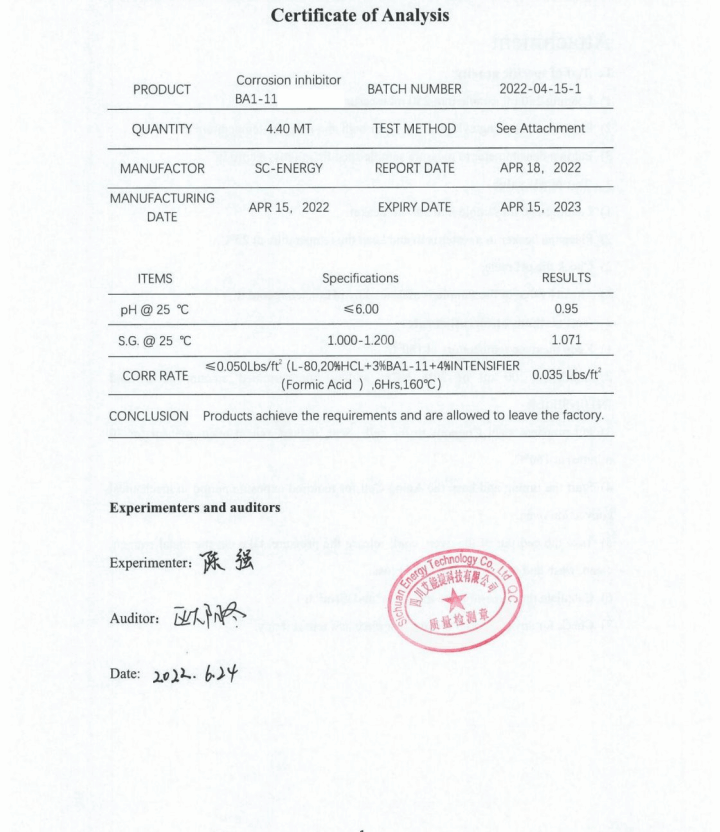

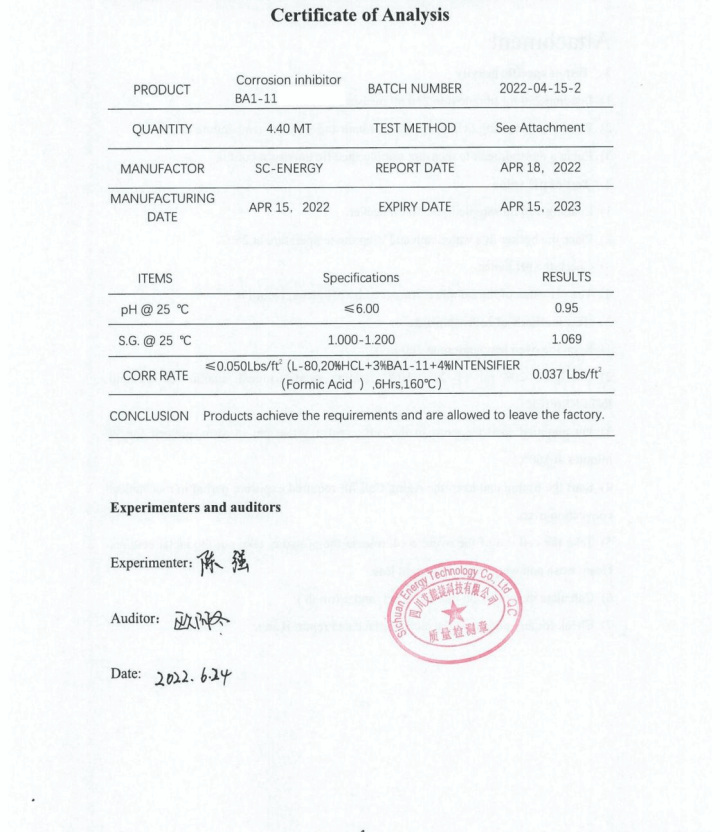

Acid corrosion inhibitor BA1-11

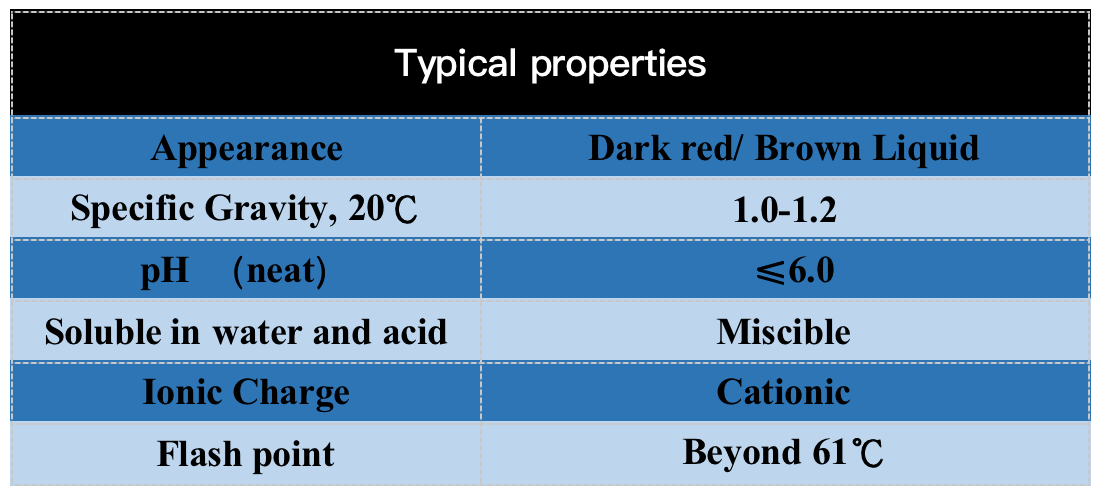

Appearance:dark red

PH:<=6

Flash Point (Closed-up) ,('C ):beyond 61

Density, (g/cm3):1.0-1.2

Analysis Features:miscible in water and acid

You May Like

You May Like

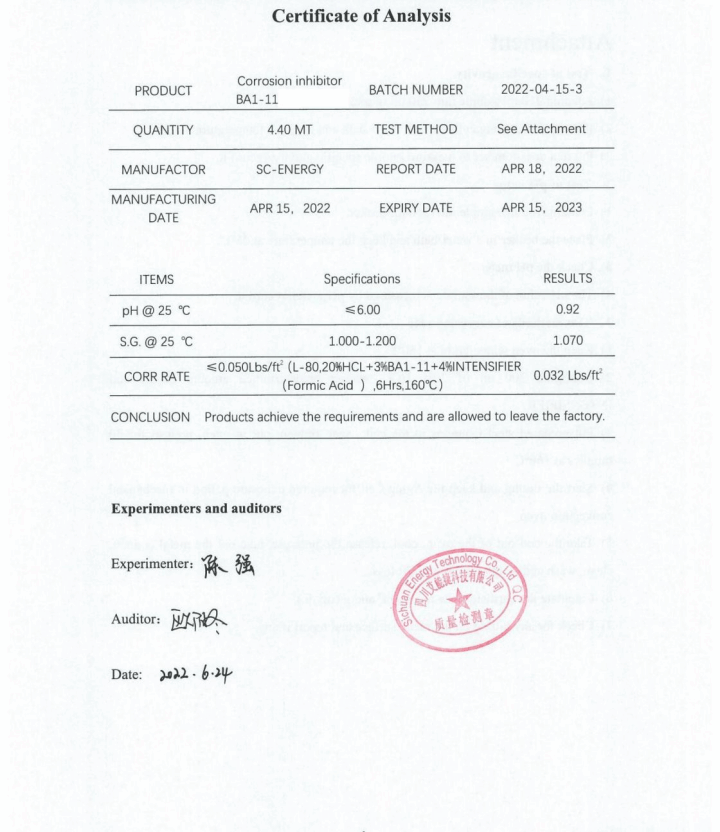

Product details

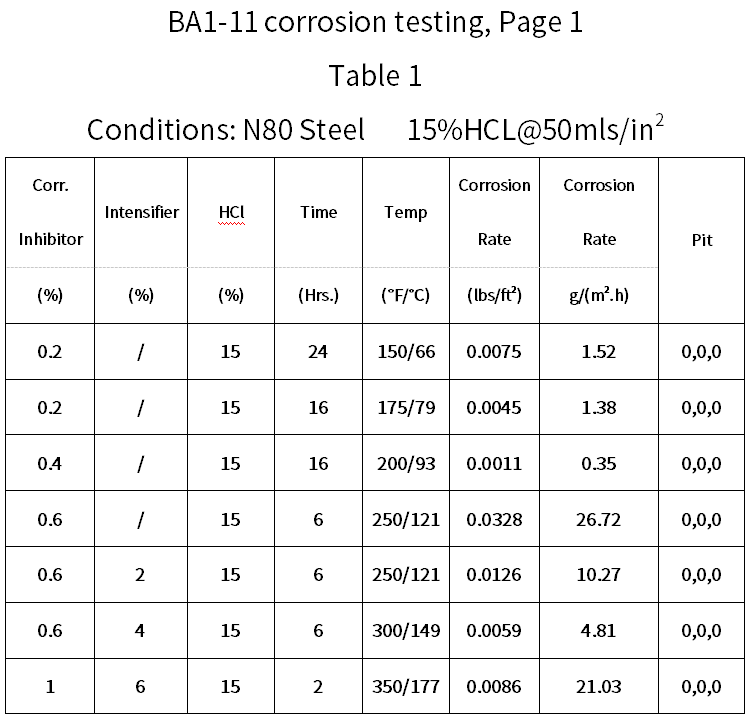

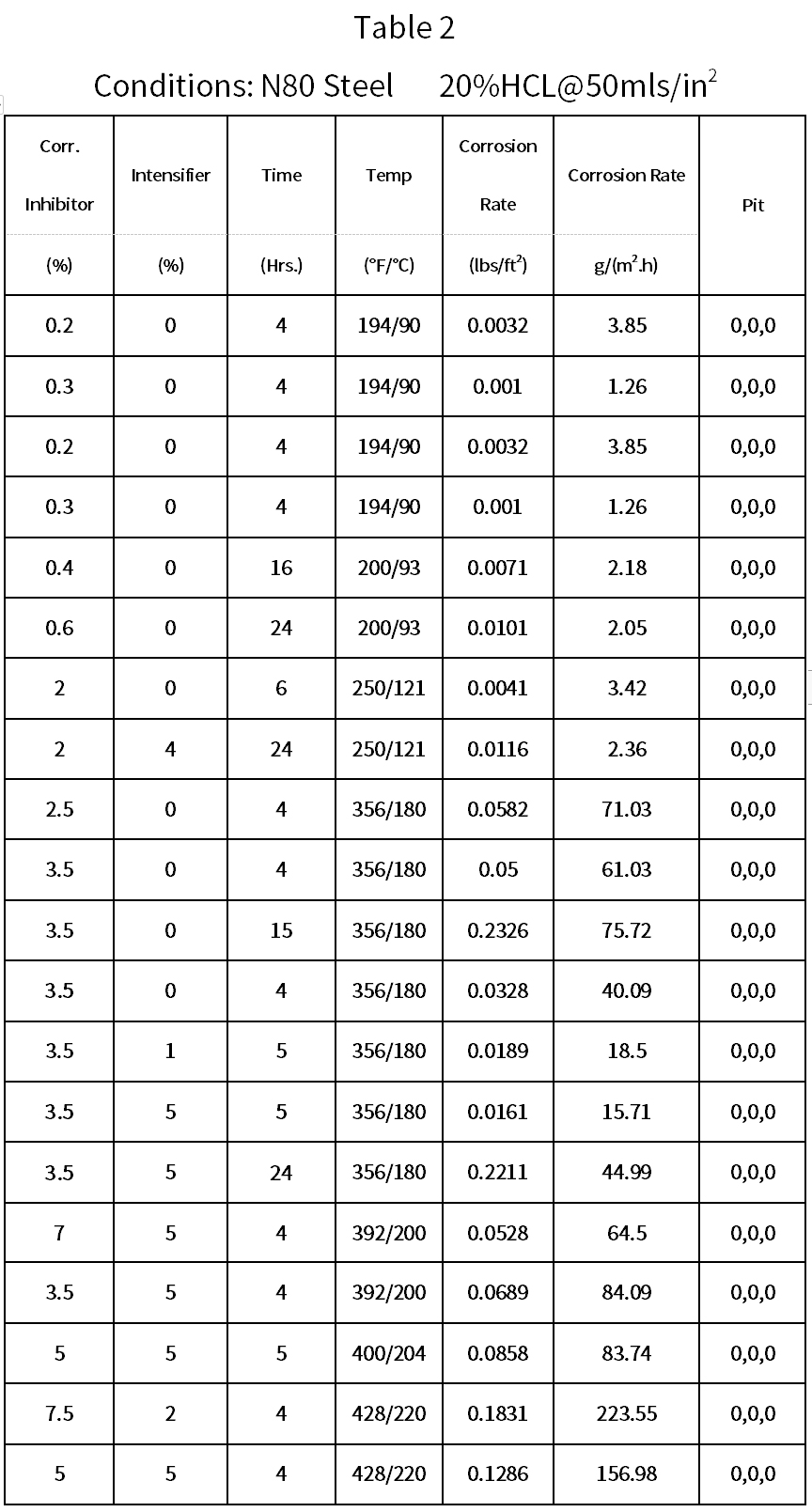

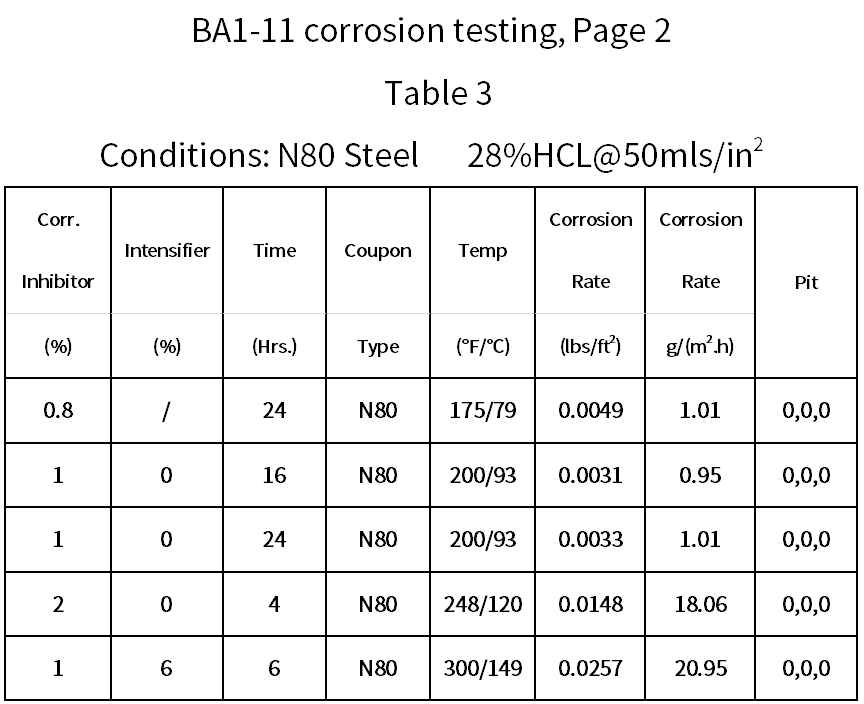

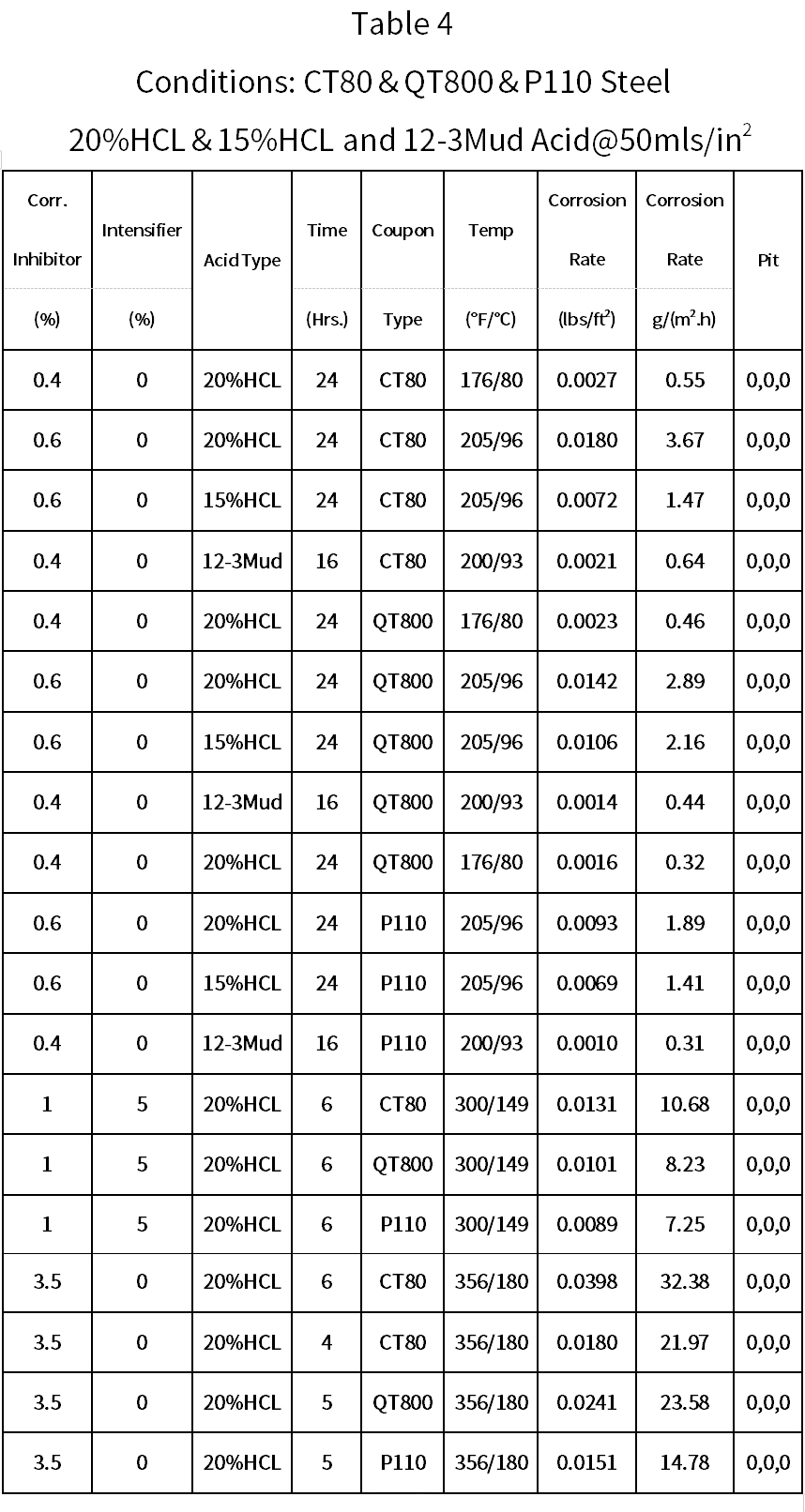

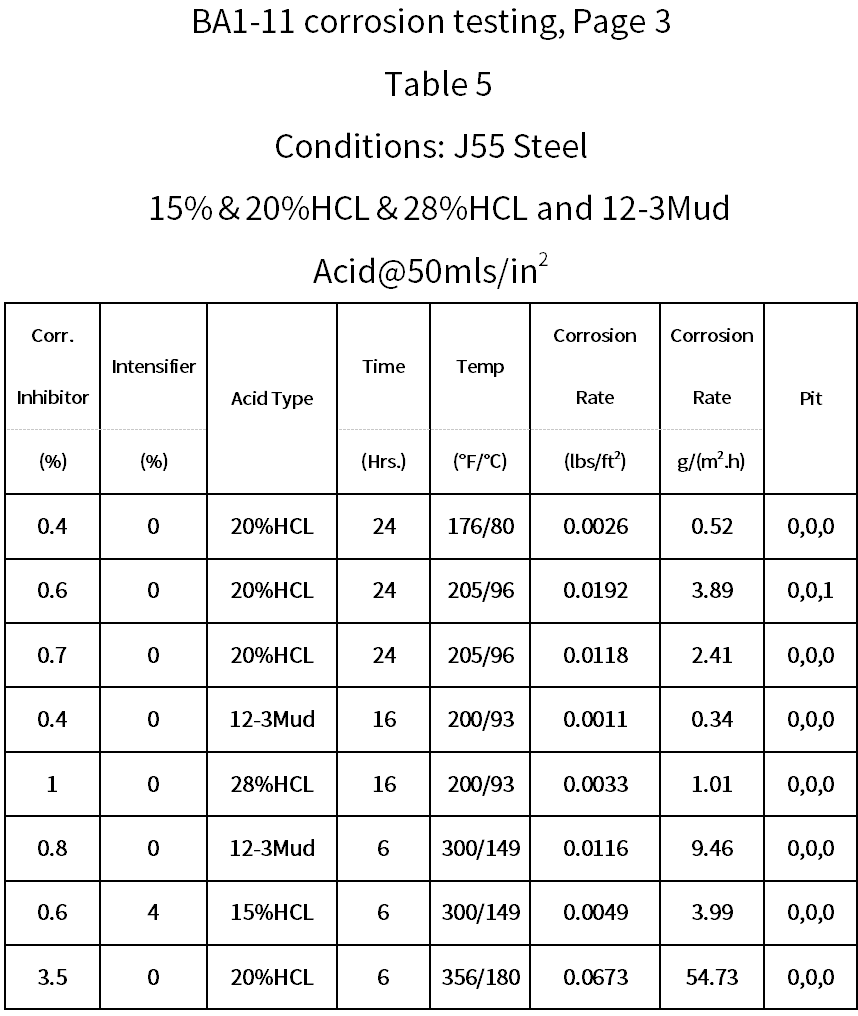

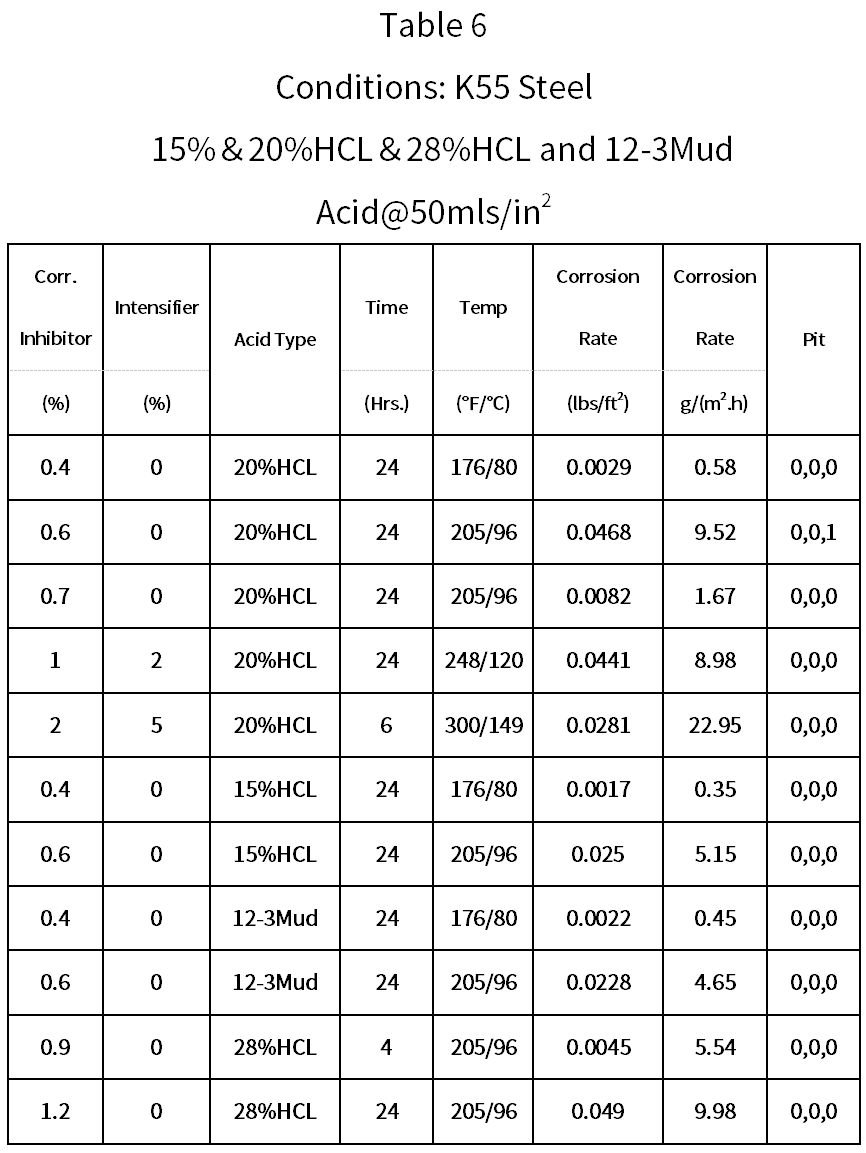

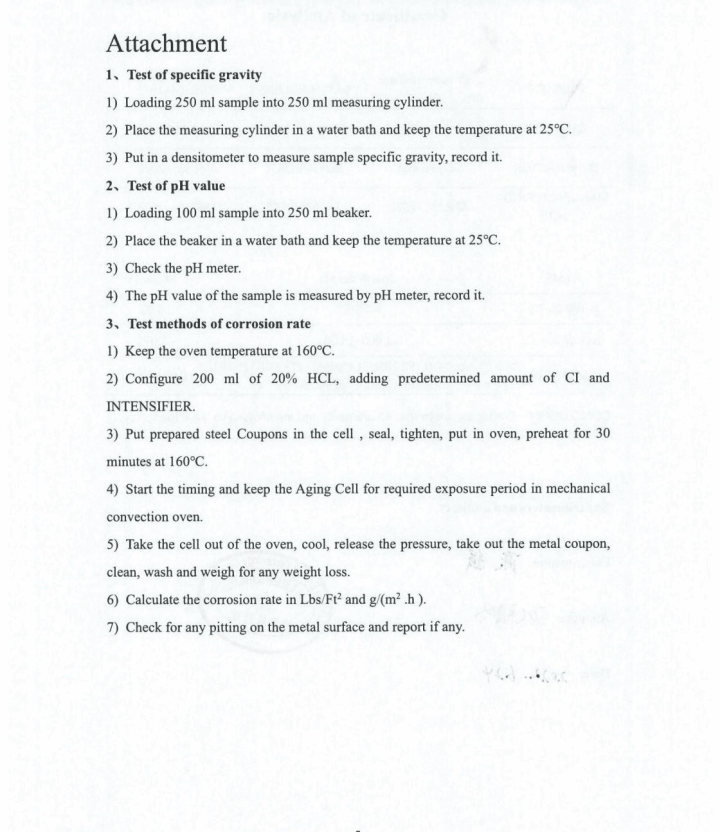

HCl of any strength has an undesirable reaction on steel. The amount of damage will depend upon contact time, acid strength, and temperature conditions. As bottom hole temperatures increase, the effectiveness of many moderate temperature acid inhibitors decreases below desirable protection levels. The corrosive action of acid on steel at high bottom-hole temperatures can be greatly reduced at temperatures up to 350°F)by adding BA1-11 to the acid mixture.

Applications

Features and Benefits

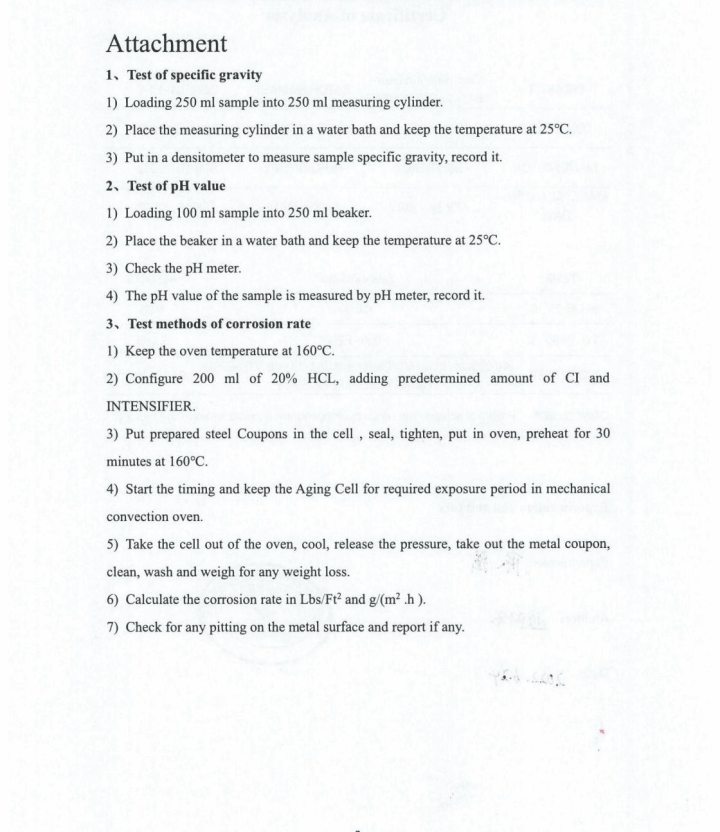

Technical Data

Usage

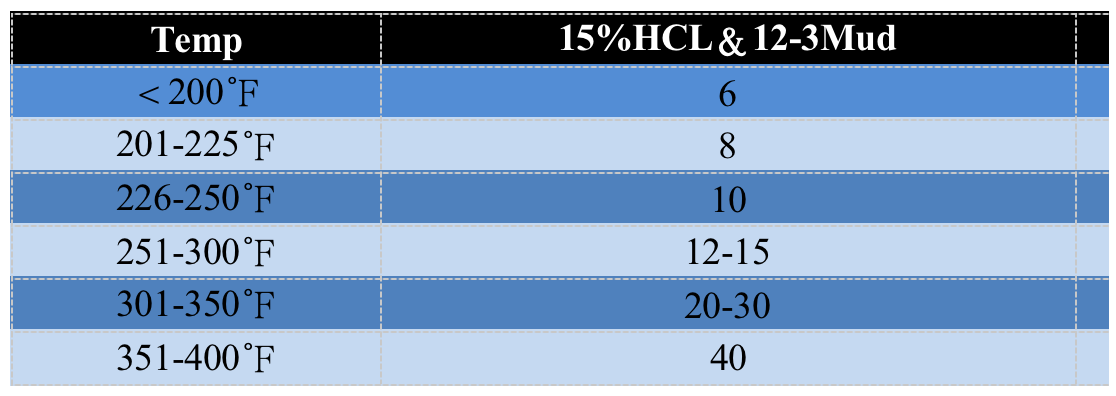

GALLONS BA1-11 PER 1000 GALLONS ACID

Concentration is dependent on acid type, strength, bottom-hole temperature, contact time, and additional additives.

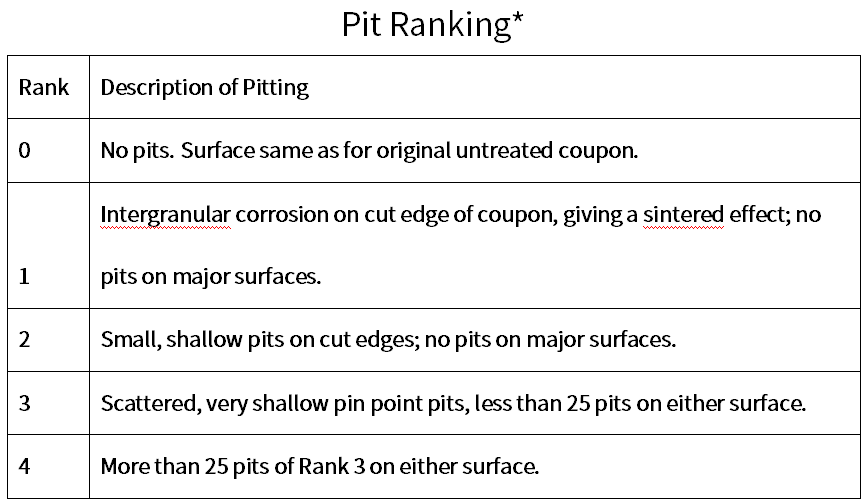

Pitting represented by Ranks 1 through 4 usually are not considered serious . Ranks 1 and 2 are on surfaces that normally do not occur in oil well tubular goods . This corrosion depends largely on Ihe method of pipe manufacture, for example, heat treatment. Ranks 3 and 4 frequently are accompanied by very low corrosion rates and often have been observed with arsenic inhibitors.

*-SPE 5644,C.F.Smith,F.E.Dollarhide & Nancy J.Byth; Dowell. Presented at 50th Annual Meeting of SPE, Dallas, TX9/28-10/1/75.

Global Hotline

+86 400-881-5588

If you have any questions, please contact the customer service email: servic@atoilgas.com

Service Time:

Monday to Friday, 10:00 to 17:00 Beijing Time

Scan and follow us

Scan and follow us