Online Service

Online Service

2024-01-25

Views:1797

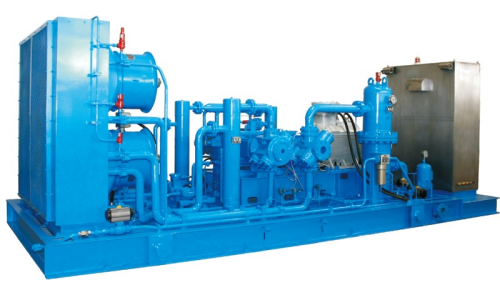

FB series compressor is a fully balanced, reciprocating compressor with variable working conditions, which has the advantages of high speed, compact structure economic use, easy operation and convenient maintenance. The driver is flexible, the diesel engine, electric motor and natural gas engine can be used as required.

This series of compressors can be widely used in oil and gas field test gas recovery wellhead gas gathering and treatment, gas lift oil and gas recovery, offshore platforms and pipeline gas booster and transmission.

Performance Parameters:

Inlet gas temperature | ambient temperature |

Inlet pressure range | 0.1~ 20MPa(g) |

Discharge temperature |

|

Capacity | 300~ 5000Nm3/h |

Product Table:

Structure | SN | Model | Stroke in(mm) | Throws | connecting rod center distance(mm) | Dia. Of pist on(mm) | Rated Power(kW) | Max. Rod(kN) | Rated Speed (RPM) |

Fully balanced design | 1 | FBC312 | 3.15(80) | 2 | 227 | 35 | 210 | 50 | 1500 |

2 | FBC314 | 3.15(80) | 4 | 227 | 35 | 420 | 50 | 1500 | |

3 | FBA602 | 6(152.4) | 2 | 431.8 | 63.5 | 2240 | 250 | 1200 | |

4 | FBA604 | 6(152.4) | 4 | 431.8 | 63.5 | 4480 | 250 | 1200 |

Technical Features:

Fully balanced reciprocating structure,completely eliminating unbalanced forces and torques; high speed available with motor and engine direct drive; small unit size, low vibration and low noise ; can be used for skid-mounted or truck-mounted compressor; process gas air-cooling, natural cylinder cooling; control system adopts PLC visualization intelligent control.

![]() High speed.

High speed.

![]() Completely symmetrical and fully balanced design, eliminating the unbalanced torque when the crankshaft is running.

Completely symmetrical and fully balanced design, eliminating the unbalanced torque when the crankshaft is running.

![]() Standardized, series and modular design, flexible configuration and reliable technology.

Standardized, series and modular design, flexible configuration and reliable technology.

![]() Air-cooled cylinder, eliminating the need for cooling pipelines.

Air-cooled cylinder, eliminating the need for cooling pipelines.

![]() Provide short compact single chamber (Type I) and long single chamber (Type II) distance piece commonly used in oilfield according to different design requirements.

Provide short compact single chamber (Type I) and long single chamber (Type II) distance piece commonly used in oilfield according to different design requirements.

![]() Cylinder can be used as double action cylinder and single action cylinder (stage differential cylinder) with flexible design combination.

Cylinder can be used as double action cylinder and single action cylinder (stage differential cylinder) with flexible design combination.

![]() Cylinder adopts larger inlet and outlet valve chambers to minimize gas pulsation at the inlet and outlet ports.

Cylinder adopts larger inlet and outlet valve chambers to minimize gas pulsation at the inlet and outlet ports.

![]() Seal packing at each row are exchangeable, reducing the number of spare parts, differential pressure of packing sealing is up to 25MPa

Seal packing at each row are exchangeable, reducing the number of spare parts, differential pressure of packing sealing is up to 25MPa

![]() The moving parts of compressor are lubricated by two-way oil feed, and the main oil circuit is top-mounted oil inlet for reliable lubrication, with more reasonable structure and convenient to clean.

The moving parts of compressor are lubricated by two-way oil feed, and the main oil circuit is top-mounted oil inlet for reliable lubrication, with more reasonable structure and convenient to clean.

![]() The crankshaft is top-mounted oil inlet and set with main bearing temperature detection.

The crankshaft is top-mounted oil inlet and set with main bearing temperature detection.

Application:

This type can be applied to CNG main station, test gas recovery, 8 sets of sour gas booster units (5% H.S) were applied to CNPC Tarim gas field, the highest operating time of a single unit has exceeded 7,750 hours; the first ultra-low temperature BOG recovery compressor was successfully applied to CNOOC Tianjin floating LNG terminal station; oil-free lubrication compressors were used in LNG plant to boost raw gas in Southwest Bureau and inner Mongolia ; more than 100 units of compressors were supplied to Chongqing Fuling Shale Gas 49# gas station , and the total daily output of wells gas was increased by 41.3%; the integrated high-speed fully balanced compressor (1500r/min) for wellhead gas recovery, which integrates separation and dehydration, metering and filing, was used in Fuling Jiaoshiba Shale Gas Recovery and North China Daniudi Test Gas Recovery, which have accumulatly produced nearly 50 million cube meters of gas recovery.