Online Service

Online Service

Top

Top

Service

Service

Feedback

Feedback

You May Like

You May Like

Product details

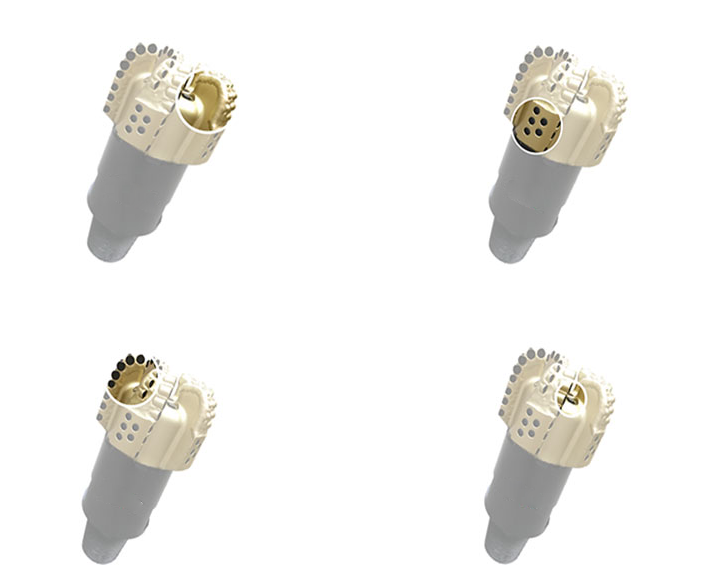

Steel Body PDC Bit Advantages

1、The Steel body PDC bit body is made of AISI 4145H round steel

2、Bit diameters range from 3" to 36" with a variety of cutters and optional back-out cutters as well as various blade counts.

3、Every Steel body bit shall have heat treatment, to improve the mechanical properties of steel, to eliminate residual stress and improve the cutting performance.

4、Each blade surface shall be welded with hardened material to increase wear resistance and erosion resistance.

5、 has new technology hard facing material and sleeve to prevent washout the nozzles.

Suitable Formation:

Various hardness rocks or mud except for the hardest hardness or ununiform rocks like cobble.

Application:

Water well, Petroleum & Gas, Water well, mining and tectonic.

In terms of the metallurgical properties of the two materials, steel and matrix are the exact opposite of each other. The tungsten carbide particles in the matrix are metallurgically bonded to form a hard and brittle composite material that is more wear-resistant than steel and is preferred for high solids content drilling muds. Steel, on the other hand, is ductile, tough, and well able to withstand greater impact loads.

Steel body PDC bits are milled from billet steel for a stronger, tougher construction. While steel body PDC bits are easier to manufacture, the production of matrix PDC drill bits is a rather time consuming process.

Although matrix and steel body bits perform the same task, that is drilling, the difference in their structural capabilities results in different bit geometries. The main factors affecting the design of steel body PDC bits and matrix body bits are mechanical design parameters, hydraulic conditions and the properties of the rock being grilled.

Global Hotline

+86 400-881-5588

If you have any questions, please contact the customer service email: servic@atoilgas.com

Service Time:

Monday to Friday, 10:00 to 17:00 Beijing Time

Scan and follow us

Scan and follow us