Online Service

Online Service

Top

Top

Service

Service

Feedback

Feedback

Drilling rig

Type:ZJ10/ZJ15/ZJ20/ZJ30/ZJ40/ZJ50/ZJ70/ZJ90

Zone of application:Plain/Mountain/Desert/Arctic/Island

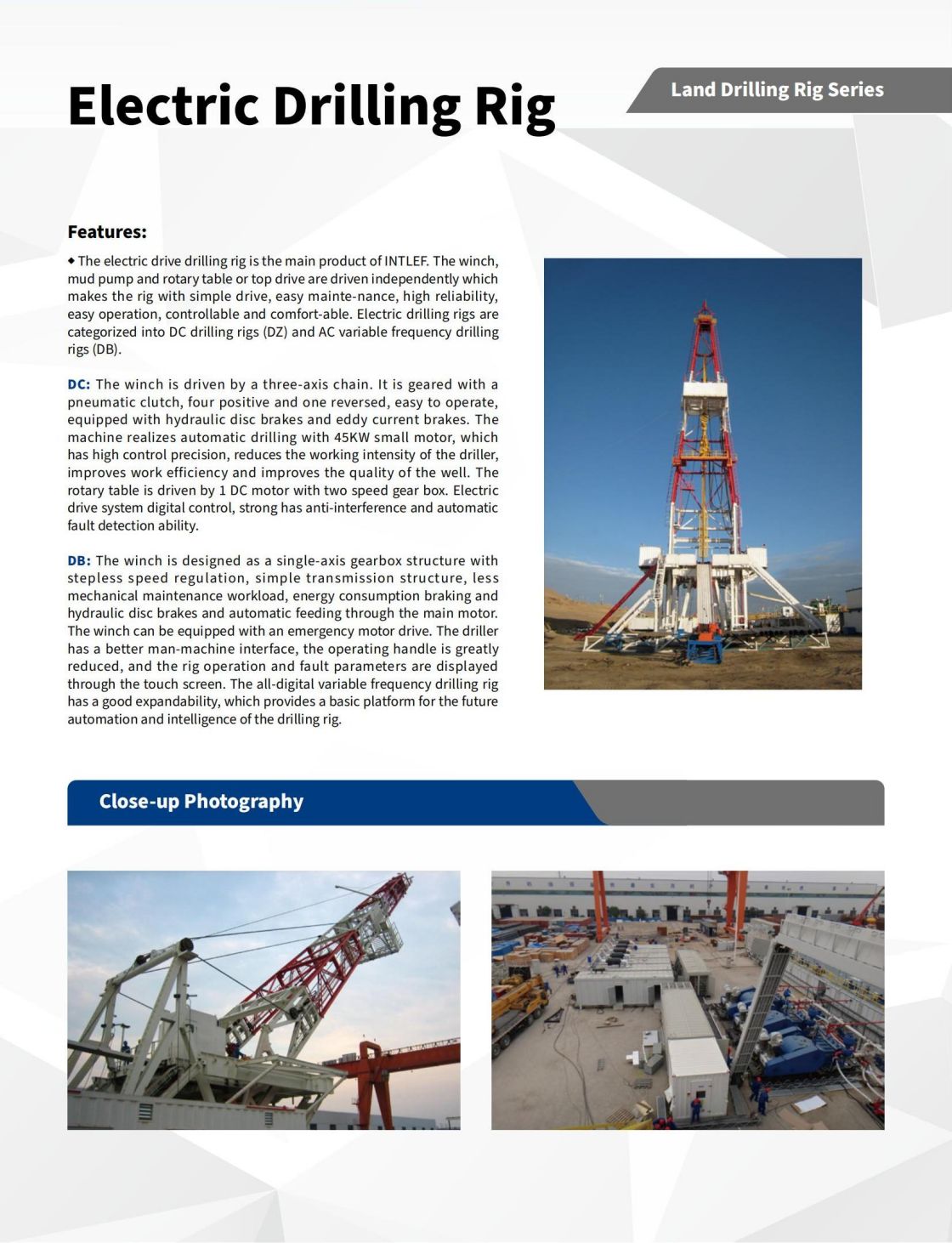

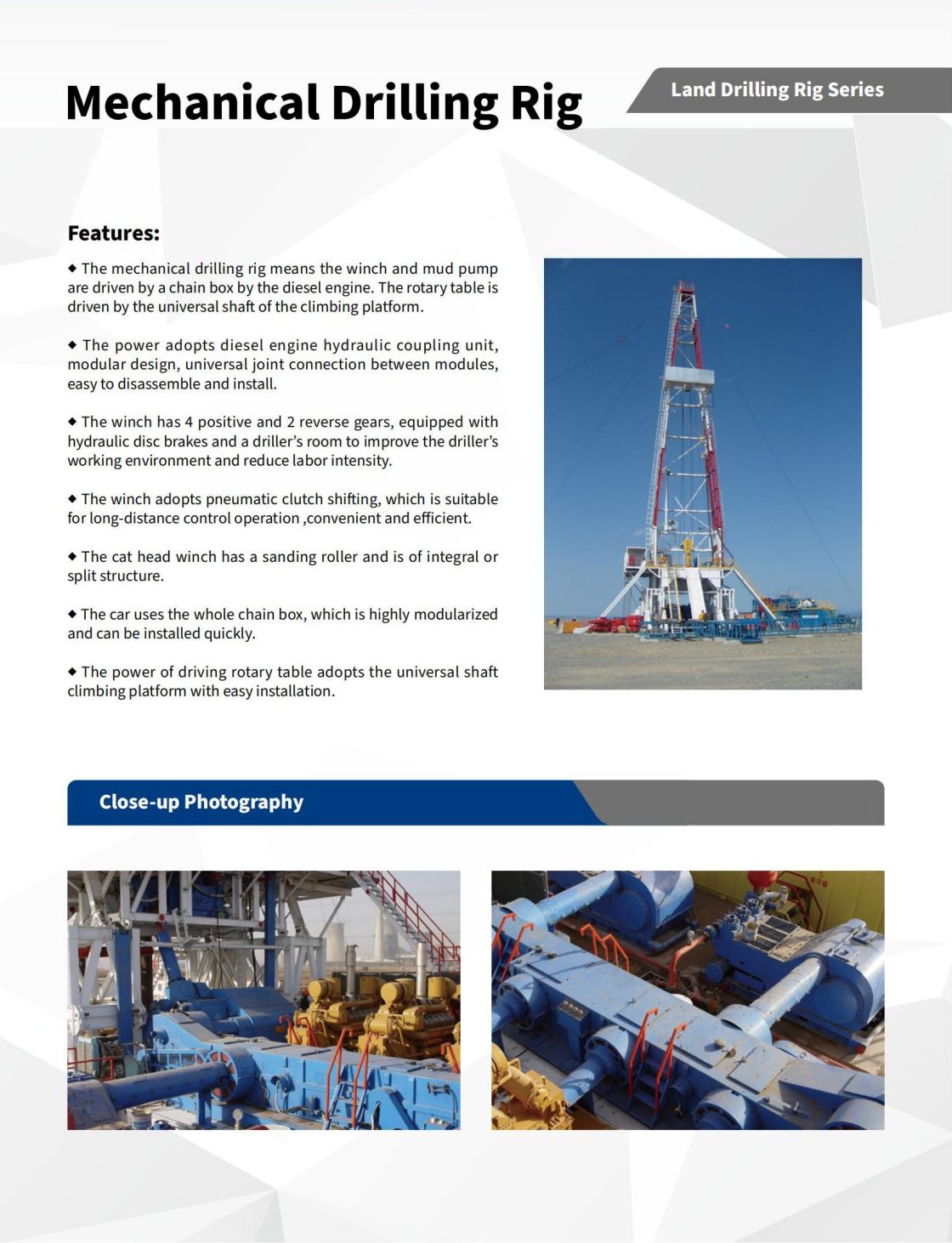

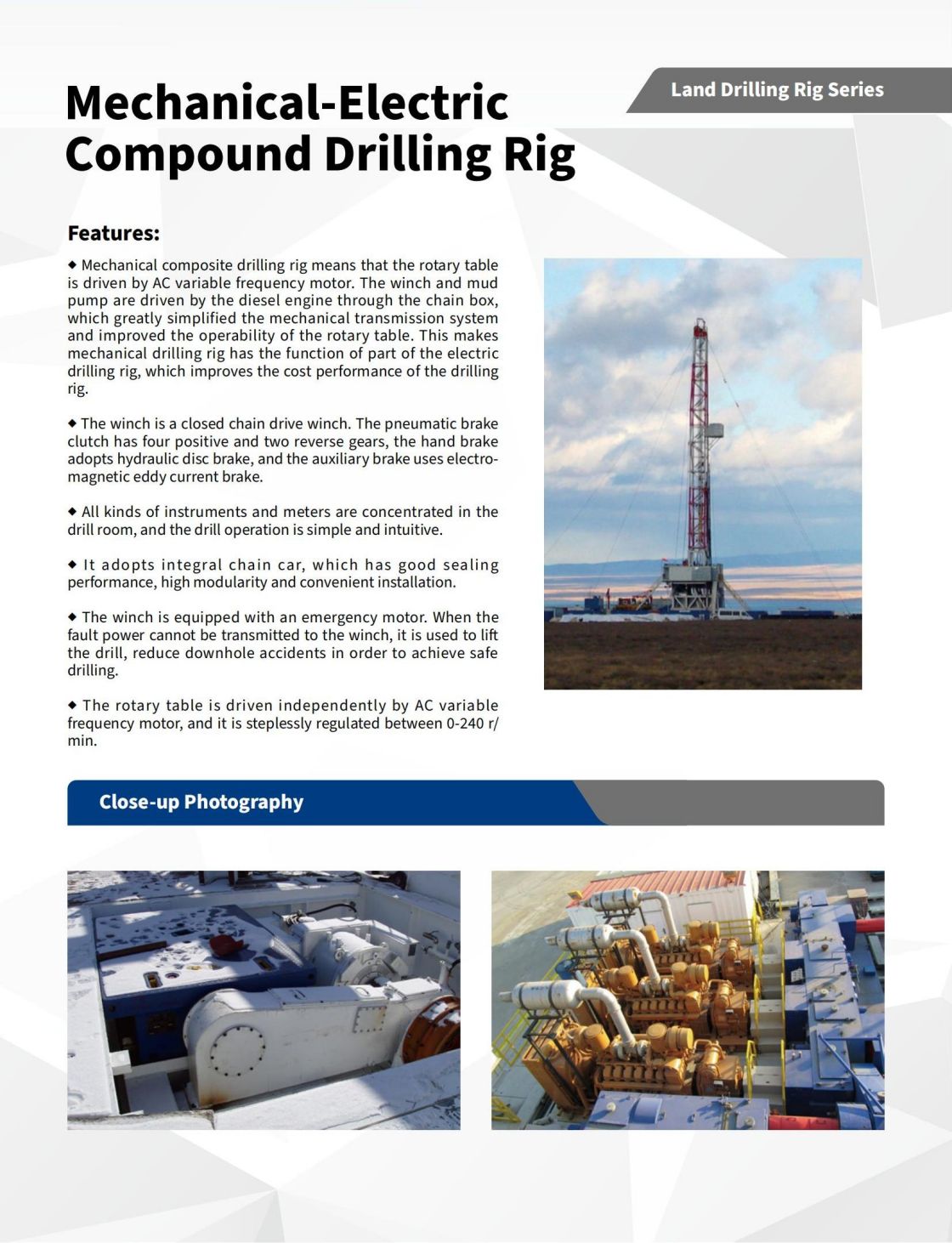

Driving mode:Electric/Mechanical /Mechanical-Electric

Loading method:Truck-mounted/Skid-Mounted/Trailer-Mounted

You May Like

You May Like

Product details

Skid-Mounted:

1. Drilling rig drive can be divided into mechanical drive, alternating current drive, direct current drive, compound drive and other forms, with reasonable power matching, high transmission efficiency and reliability. The machine layout is reasonable, the use of standardized, modular design, a variety of combinations of versatility, interchangeability, high degree of integration, installation, transport fast.

2. The derrick structure is in the form of type A, type K, etc., which is assembled in sections, connected by bolts or pin shafts. The lifting is divided into vertical lifting in sections or overall rotating lifting, and equipped with buffer device in place to ensure stable and safe positioning.

3. The substructure is in the form of spiral lift, double lift, box stacked, telescopic and so on.

4. The main brake adopts band brake or hydraulic disc brake, the auxiliary brake adopts pneumatic water-cooled push-disk brake, electromagnetic eddy current brake, or the auxiliary brake is made by energy consumption braking of ac frequency conversion motor.

5. Rotary table drive is divided into combined mechanical drive and independent ac or dc drive, which can realize the positive rotation, reverse, suspension, release of the rotary table, equipped with reverse torque release device, to ensure the safe release of rotary table drilling string torque.

6. Complete peripheral equipment such as solid control, well control, high-pressure pipe manifold, electronic control system, mud pump group, oil and water tank, etc. Modular design, standardized interface, can be arbitrary matching, can be customized.

Trailer-Mounted:

1. Trailer mounted drilling rig drive can be divided into diesel engine drive, alternating current drive, direct current drive and other forms, with reasonable power matching, high transmission efficiency, high reliability, compact structure, high degree of assembly, small footprint.

2. Adopt the chassis of heavy-duty semi-trailer specially used for petroleum, with good mobility and off-road.

3. The main brake adopts belt brake or hydraulic disc brake, and the auxiliary brake adopts pneumatic push-disc brake and pneumatic clamp disc brake.

4. The mast set with two sections at the front opening, which can be divided into forward tilting type and vertical type, hydraulic cylinder lifting and stretching, and is equipped with wind tight rope and anti-overturn tight rope.

5. The rotary drive system can realize the positive rotation, reverse rotation, suspension and disconnection of the rotary table, and is equipped with the reverse torque release device to ensure the safe release of the rotary table drilling string torque.

6. The drill floor adopts the telescopic or spiral lifting structure, the floating platforms on both sides can be turned over, and equipped with a line of double Bridges, which cannot be detached from the load during operation. Table height, size, layout can be customized.

7. Complete solid control, well control, high-pressure manifold, electronic control system, mud pump group, oil and water tank and other towing peripheral equipment, as well as supporting conventional equipment. It can be matched arbitrarily or customized as required.

Truck-Mounted:

1. The Truck-mounted drilling rig is driven by diesel engine with reasonable power matching, high transmission efficiency, high reliability, compact structure, high degree of assembly and small footprint.

2. Self-made heavy-duty chassis, equipped with hydraulic power steering system, with good mobility, off-road and transverse stability.

3. The main brake adopts band brake or hydraulic disc brake, and the auxiliary brake adopts pneumatic push-disc brake, pneumatic clamp disc brake or water brake.

4. The mast set with two sections at the front opening, tilting forward or standing upright, lifting and stretching of the hydraulic cylinder, and is equipped with wind guy lline and anti-overturn guyline.

5. The rotary table drive system can realize the positive rotation, reverse rotation, suspension and disconnection of the rotary table, and is equipped with the reverse torque release device to ensure the safe release of the rotary table drilling string torque.

6. The drilling floor adopts the telescopic or spiral lifting structure, the floating platforms on both sides can be turned over, and the sledding can be hoisted and transported.Table height, size, layout can be customized.

7. Perfect peripheral equipment of solid control, well control, high-pressure manifold, mud pump unit, oil and water tank, etc. It can be matched arbitrarily or customized as required.

Global Hotline

+86 400-881-5588

If you have any questions, please contact the customer service email: servic@atoilgas.com

Service Time:

Monday to Friday, 10:00 to 17:00 Beijing Time

Scan and follow us

Scan and follow us